North America’s Leader in State of the Art Energy Management

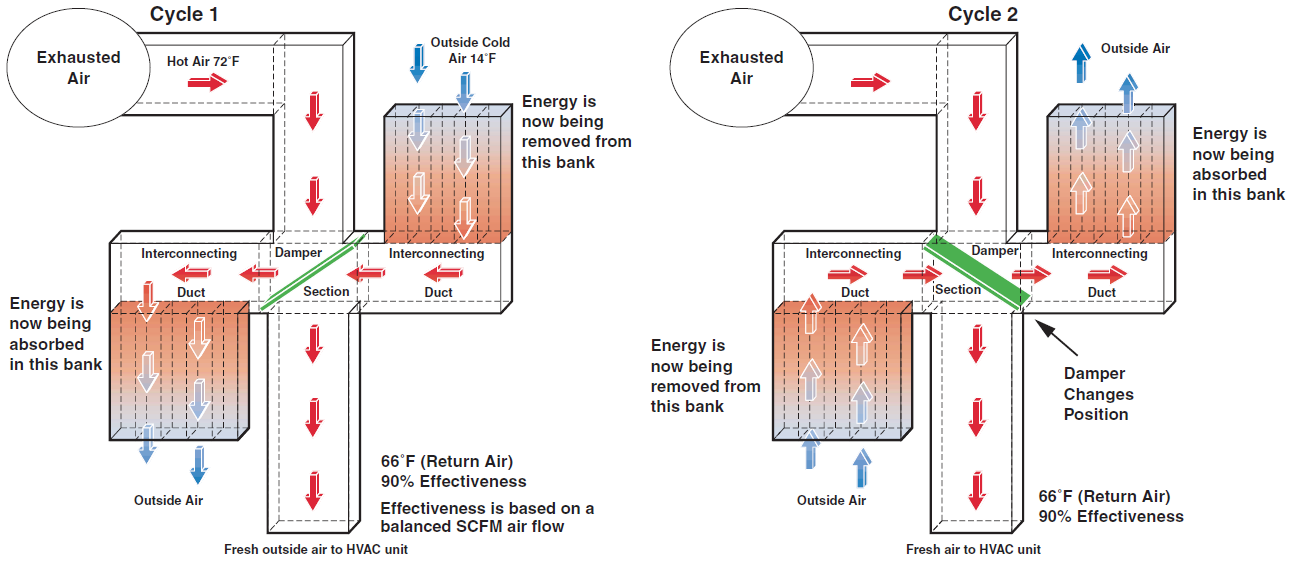

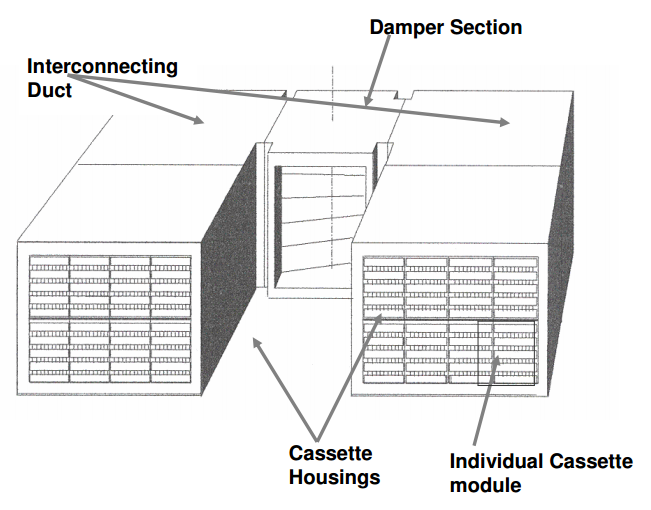

Our patented technology is both simple and extremely effective. As air is exhausted from a building or process, our two positional damper (which is the only moving part) directs the flow of air through one of the banks of pure 1100 aluminum alloy plates whose surface area has been maximized to capture energy from the exhaust air stream. At the same time, outdoor air is being drawn through the opposite heat exchanger “cassette” bank, returning the previous stored energy to the space, or process.

As our damper changes position, (standard cycle is 70 seconds) the entire system works in REVERSE FLOW®. Outdoor air is now drawn through the newly energized cassette bank where the captured energy is released, returning it to the incoming air stream. The modular design, also with minimal pressure drop, allows ultimate flexibility as both a new installation packaged unit or a retrofit utilizing existing fans. Our unique design also allows for high temperature heat recovery (450°F) generated from manufacturing processes. This enables applications in industrial facilities, commercial office buildings, institutional settings (schools, colleges/universities), wherever fresh air and cost consciousness are at a premium.

With our stationary design, REVERSE FLOW® and special plate technology we are able to size our energy absorbing cassette units to greatly enhance our ability to recapture the waste energy.

Because of the depth of our cassette units, 38” in all, a gradual heat transfer takes place assuring an even energy dissipation into the incoming air stream, making for an extremely consistent return air temperature.

System Highlights:

System Highlights:

- Modular Cassettes

- Self-Cleaning

- One Moving Part

- Adjustable Latent Recovery

- Interior and Double Walled Exterior Units

- Zero Frosting (to -40°F)

- Pressure Drops to Max. 1.02 Inches

- Sensible and Latent Recovery

- Process Applications up to 450 F

- No Filters Required

System Features:

Operational:

The unit recovers energy from exhausted air. It has two energy accumulating cassette banks; each cassette consisting of specially designed plates made of 1100 aluminum. The plates are installed parallel to each other with a 4mm gap between. The shapes of the plates are designed to create airflow with a high-energy transfer capacity. The supply and exhaust air is guided alternately through these aluminum cassettes. While the exhaust air is moved through one cassette bank, the opposite bank is taking in outside air and transferring the energy that has been stored in the plates on the previous cycle. The standard for damper change is 70 seconds but is adjustable for different environments.

Industrial Grade Construction:

The high-grade aluminum plates are assembled in modules with 63 corrugated plates per “cassette” and are secured with a stainless steel frame and storm louvers. Any number of these cassette modules are enclosed in a double walled, 16 gauge, galvanized steel enclosure with a full 2” of insulation. All this is built upon a full structural steel base frame.

Because of our REVERSE FLOW® design, our units are self-cleaning and most applications do not require filters. An inspection every 5 years is recommended for normal operating conditions and if needed the cassettes are easily removed and can be power washed with soap and water or other mild cleansing solutions.

Cross Contamination of Air Streams:

Realistically there is range between 2% to 4% of potential cross contamination generated from the standard energy recovery unit. This is due to the air volume left in the cassettes, interconnecting duct and damper housing when the damper changes position. The reason for the range is dependent upon the final size of these three sections when constructed, the timing of the damper switch point, and air velocity. It should be noted that this stale air should be thought of as building air that never left the space. The face velocity of the exhaust stream through the cassette is 350 to 546 FPM dependent upon sizing. At 6.6 feet per second a single directional high speed exhaust stream would make the issue of the supply air mixing with the just exhausted air difficult at best, as the one second delay of the changing damper would push stale air away from unit. When the unit Reverse Flows, the intake of outside air does not form a single directional pattern, and air is drawn into the unit from all different directions. A simple illustration of what we are referring to would be the basic act of blowing out a candle. It is very easy to blow the candle out at a distance of six inches, but when we try to extinguish the flame by inhaling it out from that same six inches it’s all but impossible. Remember that you also have the ability to configure the direction of the cassette banks so they are facing opposite each other to further reduce any chances of unwelcome stale air return.

Furthermore in order to prevent an increasing crossover contamination, we advise to place the cassettes directly against the outside wall when the unit is situated inside a building or use our multiple damper configurations. When placed outside, this problem will not occur.

Chlorine Environments:

On exposure to air an oxide forms immediately on our high-grade aluminum plates. The aluminum oxide that forms is a corrosion resistant self-protecting coating. The oxidation process stops under normal conditions or is drastically reduced in hostile “process” applications. The plates can be made from high-grade marine aluminum alloy, which elevates the integrity of the plates in heavy chlorine air environments.

Modularity of Design:

Because the system is built around the individual cassette module, we have the ability to tailor the provided energy recovery equipment specific to the appropriate need. Less than a .402” pressure drop is achieved with our guaranteed efficiency rates, compared to a competing product’s four size fits all application methodology that has greatly varying efficiency ranges and pressure drops totally dependent upon the CFM flowing through it. Due to the modular design, this system is ideal for both new and retrofit applications. It can be installed where other systems can’t because of our ability to work with unique space requirements.

We guarantee sensible recovery effectiveness of more than 80% summer, 90% winter. (+- 5%) with our .402 static pressure drop range. With our stationary design, REVERSE FLOW®, and special plate technology we are able to oversize our energy absorbing cassette units to greatly enhance our ability to recapture the waste energy. Because of the depth of our cassette units, 38” in all, a gradual heat transfer takes place assuring even energy dissipation into the incoming air stream, making for an extremely consistent return air temperature

Latent Recovery:

In colder months, heated indoor conditioned exhaust air passes over our previously cooled plates, condensation forms due to the large temperature variances. When the system Reverse Flows this moisture is recaptured and returned to the conditioned space. The drier the outside incoming air is, the greater the latent recovery will be. This system greatly reduces the need to humidify during the colder months. Our ability to recover latent energy assists the moisture return in winter conditions, which enhances the inside environment.

By simply changing the timing phases on our single two-position damper, or stopping it completely, we can control the amount of unwanted moisture retention as in a swimming pool environment or recapture exhausted moisture in the colder months, returning it to your facility. We are also able to control the sensible output for a VAV system when total energy recovery is unwelcome. When our damper is in a fixed position we are truly in a free cooling “Economizer” mode to take advantage of free outdoor air conditions.

No Freeze / No Defrost or Bypass Dampers Needed:

With our REVERSE FLOW® capabilities, we self defrost on every exhaust cycle. When you truly need the energy recovery we are there working without going to an expensive bypass or defrost mode. The unit has been tested to temperatures down to -40 below zero.

Variable Air Volume Capabilities :

With the growing need by engineers designing an effective system to vary the required amount of outside air, we have patented a unique methodology that allows for the same heat exchanger to flow varying amounts of outside air while still maintaining our high effectiveness. It is extremely important that the air flowing through our heat exchangers maintains its optimum flow velocity. The capability to manage these flow changes will greatly affect the overall unit performance through extreme weather conditions. If a variable air volume application is not properly managed, uncontrolled exhaust air moisture will collect within the heat exchanger and freeze at cold outdoor conditions. The overall performance of the heat exchanger will also be affected as to large a surface area is as detrimental to performance as is to small a surface area.

Effectiveness of Sensible Energy Recovery:

The effectiveness of the system is 80% summer 90% winter (+/- 5%). For calculating the effectiveness the temperature is taken from the exhaust duct before the fan and from the supply duct after the supply fan. The effectiveness is related to the balance between supply air and exhaust air. When more air is supplied than exhausted, the effectiveness will be lower. When more air is exhausted than supplied, the effectiveness will be higher. The recovery units must be sized according to the capacity of the ventilating system.

Effectiveness of Latent Energy Recovery:

When the outside temperature is higher than approximately 51° F, there will be no return of absolute moisture. When the outside temperature is 14° F or lower, approximately 70% of the absolute moisture is returned. In normal situations this phenomenon is welcome because when the outside temperature is low, a ventilating system with a large amount of outside air has a tendency to dry out a building.